The procurement function is taking on an increasingly strategic role in companies. Far from being simple cost-killers, procurement departments must deal with CSR challenges, the search for increased competitiveness, new suppliers and new sourcing methods, and finally, cost pressure. In short, they must optimize their procurement performance. They still have a negotiation role, but now play a key role in value creation, risk management, and company innovation.

But how can procurement performance be concretely defined? Which KPIs should be monitored to evaluate it? And above all, which levers should be activated to optimize it in the long term?

In this complete guide, we propose to review the key principles, monitoring indicators, and best practices to implement in order to sustainably optimize the procurement function.

What is procurement performance?

Before trying to improve it, it is essential to understand what procurement performance really covers. Often reduced to simple cost reduction, it actually encompasses a much broader scope, which also includes the quality of purchased products or services, lead times, supplier management, innovation, and the contribution to the company’s CSR objectives. In other words, procurement performance is not limited to financial results: it is a true indicator of the maturity and value creation of the procurement function.

Definition and scope

Procurement performance corresponds to an organization’s ability to achieve its strategic objectives through its purchasing activities. It is therefore measured by how the procurement function contributes to the company’s overall competitiveness.

The scope of procurement performance thus covers the entire procurement process, from the expression of the need to the monitoring of supplier relationships, including contracting, negotiation, procurement management, and continuous evaluation of the results obtained.

The 5 pillars of procurement performance (cost, quality, lead times, innovation, CSR)

To fully evaluate procurement performance, it is necessary to take into account several complementary dimensions:

Cost: this is the most obvious dimension. It includes the savings made, the total cost of ownership (also called TCO), and the control of expenses over time. To improve procurement performance, costs must be reduced.

Quality: procurement performance also involves ensuring that the goods and services acquired meet the expected level of quality and operational requirements. To improve procurement performance, maximum quality is needed, otherwise indirect risks may arise.

Lead times: good procurement management must allow the securing of delivery deadlines and avoid supply disruptions or delays impacting operations. To ensure the satisfaction of all stakeholders, it is crucial to maintain operational continuity and meet deadlines. In the case of a fixed-price contract, this control relies on the definition of precise milestones from the request for proposals. These milestones serve as benchmarks to track project progress, secure intermediate deliverables, and reduce the risk of drift, while providing better visibility for both the client and the supplier.

Innovation: the procurement function plays a key role in identifying new solutions, innovative suppliers, and promoting collaborative innovation approaches. In professional services, this is especially true since skills become obsolete quickly and dozens of new suppliers enter the market each year.

CSR and compliance: performance now includes the company’s ability to respect ethical, environmental, and social criteria in its purchases (responsible purchasing, traceability, regulatory compliance, etc.).

By combining these different dimensions, the company is able to build a global procurement approach focused on sustainable value creation rather than simple cost reduction.

Why is procurement performance a strategic lever for the company?

Once perceived as an essentially administrative function focused on negotiation, the procurement function has gradually evolved into a much more strategic role. Procurement performance now directly contributes to competitiveness, innovation, and the company’s ability to meet economic, societal, and environmental challenges.

From cost reduction to value creation

While cost control remains a central element, the most successful procurement departments today adopt a global approach oriented towards "value creation." This means they seek to optimize every link in the chain (need, sourcing, contracting, supplier relationship, innovation), in order to generate sustainable gains and improve the overall operational performance of the company. Thus, procurement becomes a lever of competitiveness, just like R&D or production. Cost reduction therefore becomes one component of the broader role of the procurement function. However, it remains a crucial lever, especially in professional services.

Examples of projects illustrating this approach:

Mistertemp’ offers a service based on technology and automation to recruit faster, with better quality, at lower cost, thus demonstrating how cost optimization and added value can be combined.

The platform SpendHQ illustrates the transformation of spending data into levers of both financial and non-financial performance.

A growing role of procurement in overall strategy

This evolution is accompanied by a strengthening of the role of buyers in the definition and implementation of corporate strategy. By managing supplier relationships, anticipating risks (disruptions, compliance, geopolitics), and integrating CSR criteria at the heart of decisions, the procurement function acts as a strategic partner of other departments (finance, innovation, production, sustainability). It is this ability to work in synergy with other functions that allows procurement to become a true driver of overall performance.

How to measure procurement performance?

As the procurement function gains strategic dimension, it becomes essential to rely on appropriate tools capable of providing a global vision and precise monitoring of activities. Digital solutions, especially those integrating monitoring modules, offer the possibility to track relevant KPIs, manage performance in real time, and make informed decisions.

These indicators serve both to evaluate ongoing actions and to more quickly identify areas for improvement to achieve strategic objectives.

Main indicators (KPIs) to monitor

To effectively manage procurement performance, it is useful to organize the indicators around the 5 major pillars of the function. Here are several examples:

Cost: savings achieved vs. budget or previous years, total cost of ownership (TCO) reduction rate, procurement coverage rate (managed spend / total spend), comparison of spending volume between two periods, gains achieved through the negotiation module

Quality: supplier non-compliance rate, number of complaints related to procurement, average quality score assigned to suppliers, evaluation of service quality by operations during timesheet declaration

Lead times: delivery deadline compliance rate, average processing time of the procurement cycle (from need to receipt), number of disruptions or delays impacting activity

Innovation: number of innovative projects carried out with suppliers, proportion of suppliers considered "innovative / strategic", number of improvement initiatives proposed by suppliers

CSR / Compliance: percentage of suppliers evaluated on CSR criteria, proportion of responsible purchases in total procurement, compliance rate with regulatory and ethical requirements

These procurement KPIs are part of a more refined data collection approach to ensure more precise and relevant management.

The 5 levers to sustainably improve procurement performance

Even before launching new tools or reviewing the organization, improving procurement performance involves implementing structuring levers that cover the entire procurement cycle. It is not about focusing solely on immediate savings, but about working in depth on processes, collaboration, and supplier relationships to generate sustainable and measurable performance. Here are the 5 priority levers to activate:

Needs analysis and spend segmentation

Before any action, it is essential to have a clear vision of the expenditures. This involves a detailed analysis of the needs expressed by the business units and a segmentation of procurement by categories. This step helps identify segments with high optimization potential, rationalize suppliers, and adapt strategies (requests for proposals, renegotiation, partnerships) according to priorities.

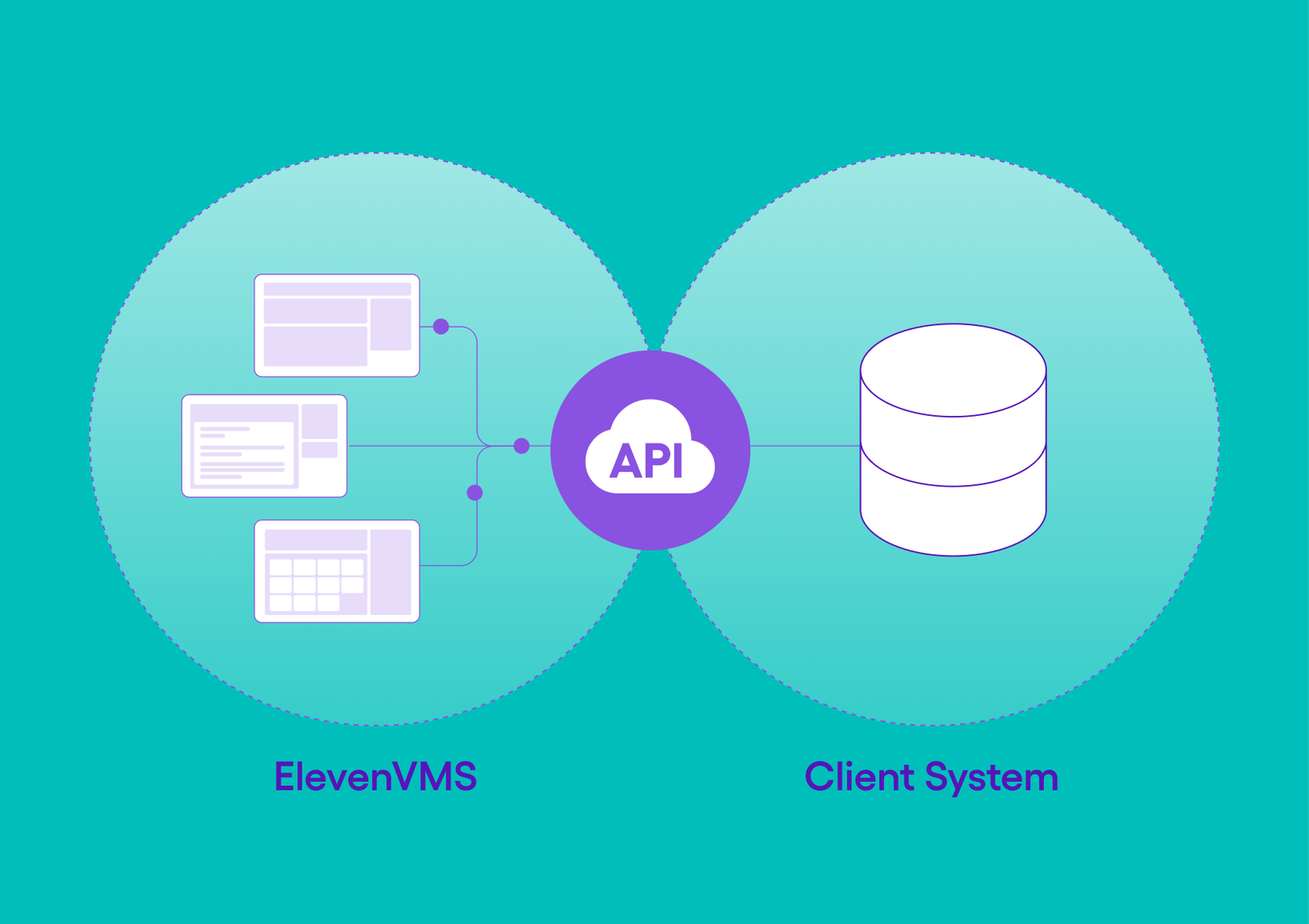

Process optimization and digitization (procurement tools)

Fluid and well-formalized procurement processes are a major performance lever. Digitization (VMS, e-procurement, e-sourcing, SRM, automation) improves traceability, accelerates cycles, ensures data reliability, and reduces administrative tasks. It also promotes better collaboration between procurement, finance, and business units.

Supplier management (SRM)

Procurement performance largely relies on the quality of the supplier relationship. Implementing Supplier Relationship Management (SRM) helps better track performance, identify risks, develop strategic partnerships, and promote innovation or co-development initiatives.

Internal collaboration / cross-functional integration

Value creation in procurement cannot be achieved without strong involvement from other departments. By working closely with R&D, operations, finance, or sustainability, procurement can better anticipate needs, co-build solutions, and secure the implementation of initiatives.

Innovation and responsible purchasing

Finally, the most advanced organizations integrate an innovation and societal responsibility dimension into their procurement strategy. This means actively seeking out new innovative suppliers, co-developing solutions, and integrating CSR criteria into procurement frameworks. This lever directly contributes to overall performance by strengthening the company’s image and creating sustainable competitive advantages.

Towards a value-oriented procurement performance

The procurement function no longer simply seeks immediate savings. Today, it adopts a global approach, focused on value creation, innovation, and resilience. Procurement performance can be measured and optimized, especially by using the right tools.

With Eleven VMS, manage all your professional services on a single, simple, and intelligent platform. Centralize your processes, optimize your costs, improve internal collaboration, and strengthen supplier relationships, all while ensuring full compliance and ease of use.

Book a meeting with one of our experts for a personalized demo.